FSMA Rule 204 Food Safety Countdown: What Restaurant Managers Need to Know Now

4 Min Read By Jeff Cowan

Better food safety has never been more in reach, thanks to advancements in traceability standards and technology. With the January 20, 2026 compliance deadline for the U.S. FDA’s Food Safety Modernization Act (FSMA) Rule 204 approaching, restaurant operators stand to gain improved confidence in the safety and quality of the food they serve. While the rule targets all links in the supply chain such as manufacturers and distributors, its ripple effects can empower restaurants to respond more effectively to food safety concerns and strengthen customer confidence.

Understanding FSMA Rule 204 and Traceability Standards

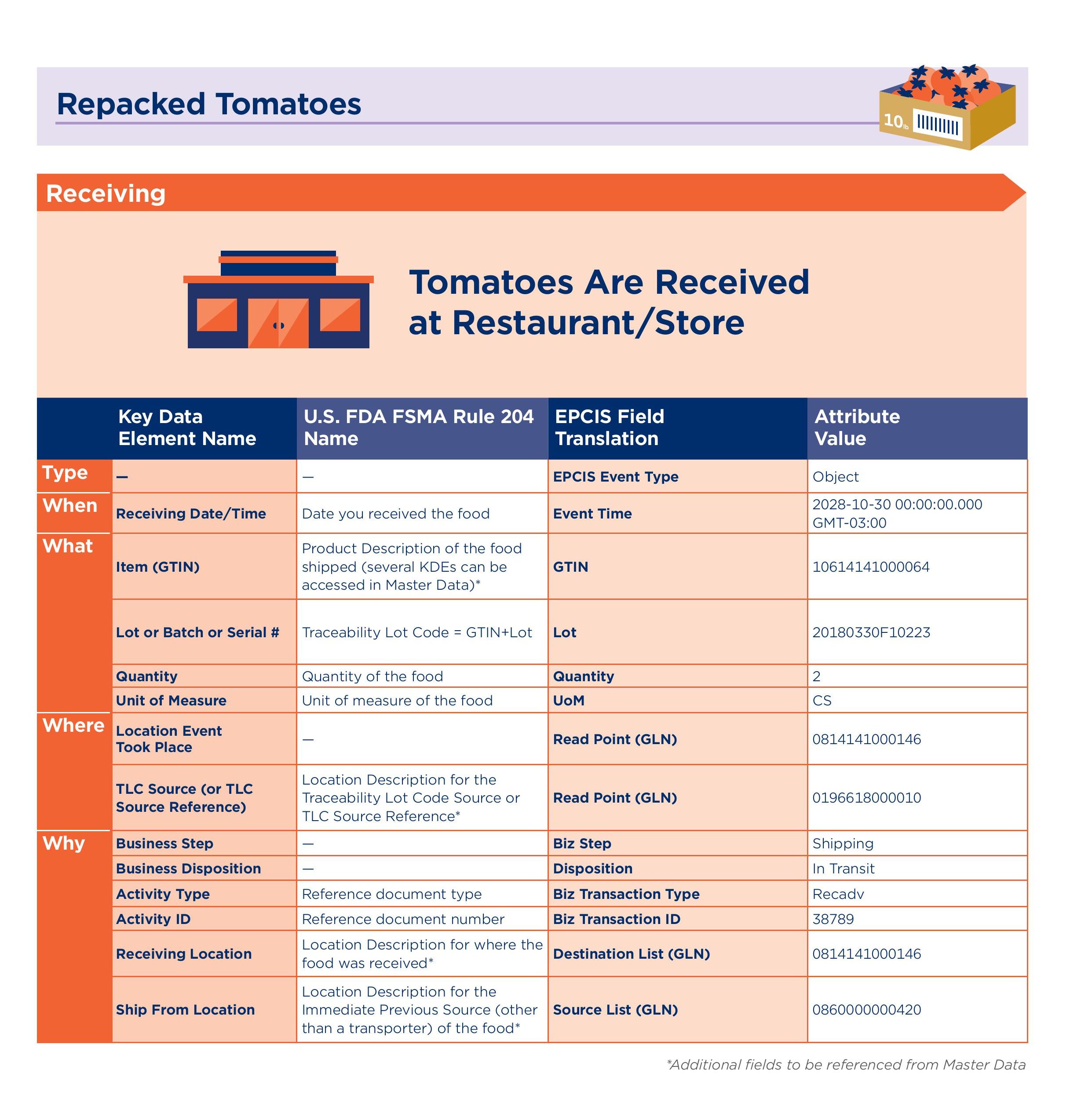

FSMA Rule 204 introduces rigorous recordkeeping requirements for Critical Tracking Events (CTEs) and Key Data Elements (KDEs) to improve traceability for foods on the FDA’s Food Traceability List (FTL). This list includes items such as leafy greens, certain cheeses, and seafood—foods identified as high-risk for contamination causing foodborne illness outbreaks. The Rule requires an up-to-date traceability plan and traceability data be made available to the FDA within 24 hours upon request in a digital format, like a sortable spreadsheet.

At the heart of effective traceability is the need for standardized, interoperable data that can flow seamlessly across the supply chain. Standards like GS1 Global Trade Item Numbers (GTINs) for product identification and Global Location Numbers (GLNs) for locations such as growing fields, distribution centers, etc., provide a framework for capturing and sharing KDEs. Additionally, GS1’s Electronic Product Code Information Services (EPCIS) plays a critical role in enabling businesses to document and share information about when and where a product changes hands. Using EPCIS helps supply chain partners ensure traceability data is consistent, accurate, and readily accessible when needed.

To realize the safety benefits of FSMA Rule 204 traceability, restaurant managers may prioritize a commitment to work with suppliers that are leveraging GS1 Standards to enable real-time, interoperable data sharing across the entire supply chain. The resulting improvements in data accuracy and reliability will help the operator respond to food safety incidents efficiently.

Why Traceability Matters for Restaurants

Traceability is deeply connected to the day-to-day operations of a restaurant. When restaurants receive food that has a journey from “farm-to-fork” fully documented with reliable supply chain data, that operator is better equipped to act quickly in a crisis. Imagine being able to identify the source of a contaminated ingredient in hours instead of days, protecting customers and avoiding business disruptions.

Beyond safety, there are additional benefits. Improved traceability means better inventory management, as restaurants have clearer insights into what’s coming in and going out of the kitchen. It can also enhance reputation, showing customers the commitment to delivering not just great food, but safe and responsibly sourced food. In a competitive industry, these advantages can set one establishment apart from another.

Steps to Strengthen Positioning

To prepare for FSMA Rule 204, begin by identifying the foods you purchase that are on the FDA’s Food Traceability List. Reach out to suppliers and ask about their compliance plans. Are they assigning the required Traceability Lot Codes (TLCs) for FTL foods? Are they employing systems that ensure their data is interoperable? This kind of dialogue will not only help you gauge their readiness but also build stronger partnerships based on mutual accountability.

Consider the tools the restaurant uses to manage records. Digital systems are becoming essential for capturing and storing traceability data in a way that’s both efficient and compliant. Whether it’s a cloud-based platform or an integrated supply chain management tool, investing in digital solutions can save time and reduce errors compared to manual recordkeeping.

After identifying the products, their sources, and a record management strategy, document the product and process flow in the traceability plan. A good plan documents how product is received, stored, and consumed in meal preparation. It also includes clear procedures for managing records, assigning responsibilities, and intercepting the use of contaminated foods in the meals the restaurant creates and serves. The plan is crucial, as it will keep the restaurant prepared for potential data requests and streamline the response in a crisis.

Turning Challenges into Opportunities

One of the common hurdles in traceability is working with smaller suppliers who may rely on manual record keeping. This doesn’t have to be a roadblock. Instead, see it as an opportunity to collaborate. Guidance exists to help businesses identify, capture and share the Rule’s required data in ways that don’t utilize digital solutions. That data can then be captured and shared on a sortable spreadsheet.

Education is another key piece. Helping teams understand the importance of traceability and the role of standardized data can foster a culture of safety and efficiency. Resources and training materials are available to make this process easier and ensure everyone is aligned.

Building a Stronger Future

By embracing traceability, you’re building a foundation for long-term success. Better data means faster responses to safety issues, less waste, and more satisfied customers who trust in the care you take with their food.

The time to act is now. By engaging with your suppliers, investing in digital tools, and understanding the importance of traceability standards, you’ll be well-positioned to thrive in an era of enhanced food safety. For more resources on FSMA Rule 204, visit https://www.gs1us.org/supply-chain/standards-and-regulations/food-safety-modernization-act.